KDF, with its extensive experience in designing reactive sputtering batch coating production systems, offers several optional features that set it apart from others. These features include:

- Optimally Designed Gas Rings: KDF’s gas rings are designed to inject the reactive gas into the sputter plasma at the target. This is particularly useful when the reactive gas is nitrogen, an intermediately chemically active gas. The gas ring effectively distributes the reactive gas, utilizing the energy of the sputter plasma to make the reaction more favorable.

- Pressure Control Package: All KDF systems are equipped with downstream pressure control and highly accurate Mass Flow Controllers (MFCs). This technique maintains a constant rate of reactive gas injection throughout the process, making it the most preferable pressure control technique during reactive sputtering.

- Prompt Gas Injection: The reactive gas Mass Flow Controllers are located as close as possible to the gas injection port on the chamber. This allows for prompt changes in flow rates with little delay.

- Power Supplies: KDF utilizes pulsed DC supplies with a wide range of pulse frequency and reverse time for conductive target reactive sputtering. This outpaces the arcing and creates a more stable high deposition rate process. KDF also specializes in reactive RF sputtering with in-house made and system-tuned matching networks.

KDF Reactive Sputtering System

KDF has extensive experience designing reactive sputtering batch coating production systems. What sets KDF apart are the several optional features that can be added to our reactive sputtering systems.

- Gas Rings

- KDF has optimally designed gas rings to inject the reactive gas into the sputter plasma at the target. This is extremely useful, especially when the reactive gas is nitrogen. Since diatomic nitrogen is considered an intermediately chemically active gas, it is best to cycle it through a plasma to crack it into monoatomic form. Essentially, the gas ring effectively distributes the reactive gas to utilize the energy of the sputter plasma to make the reaction more favorable.

- Pressure Control Package

- KDF systems are all equipped with downstream pressure control and highly accurate Mass Flow Controllers (MFCs). Downstream pressure control is where the high vacuum gate valve will automatically adjust its position to maintain deposition pressure, and the MFCs can be held at a constant flow rate. This is the most preferable pressure control technique during reactive sputtering, as a constant rate of reactive gas is injected throughout the process.

- Gas Injection

- The reactive gas Mass Flow Controllers are properly located to be as close as possible to the gas injection port on the chamber. This allows for the flow rates to be promptly changed with little delay.

- Power Supplies

- If using a conductive target to reactively sputter, KDF utilizes pulsed DC supplies with a wide range of pulse frequency and reverse time. This gives more capability to outpace the arcing and creates a more stable high deposition rate process. KDF also specializes in reactive RF sputtering with matching networks made in-house and tuned to each system.

- High rate processes for deposition of dielectric films have been developed using Pulsed DC reactive sputtering on scanning batch tools. A typical high rate process for the deposition of silicon dioxide films from a conductively doped silicon target would allow the formation of nearly one micron of SiO2 in fifteen minutes, as compared with nearly five hours when RF magnetron sputtered from a quartz target.

(Ref: Photonics Spectra, pp. 30-31, November 2002)

- High rate processes for deposition of dielectric films have been developed using Pulsed DC reactive sputtering on scanning batch tools. A typical high rate process for the deposition of silicon dioxide films from a conductively doped silicon target would allow the formation of nearly one micron of SiO2 in fifteen minutes, as compared with nearly five hours when RF magnetron sputtered from a quartz target.

- If using a conductive target to reactively sputter, KDF utilizes pulsed DC supplies with a wide range of pulse frequency and reverse time. This gives more capability to outpace the arcing and creates a more stable high deposition rate process. KDF also specializes in reactive RF sputtering with matching networks made in-house and tuned to each system.

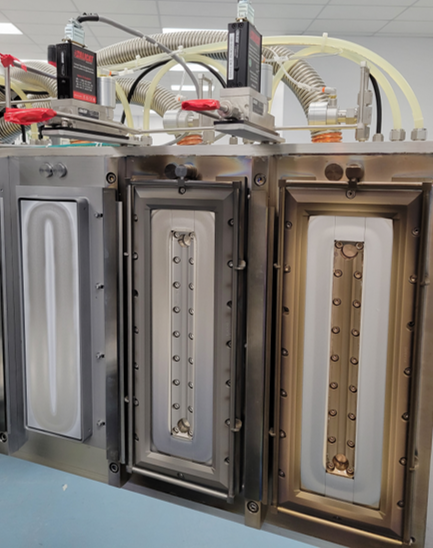

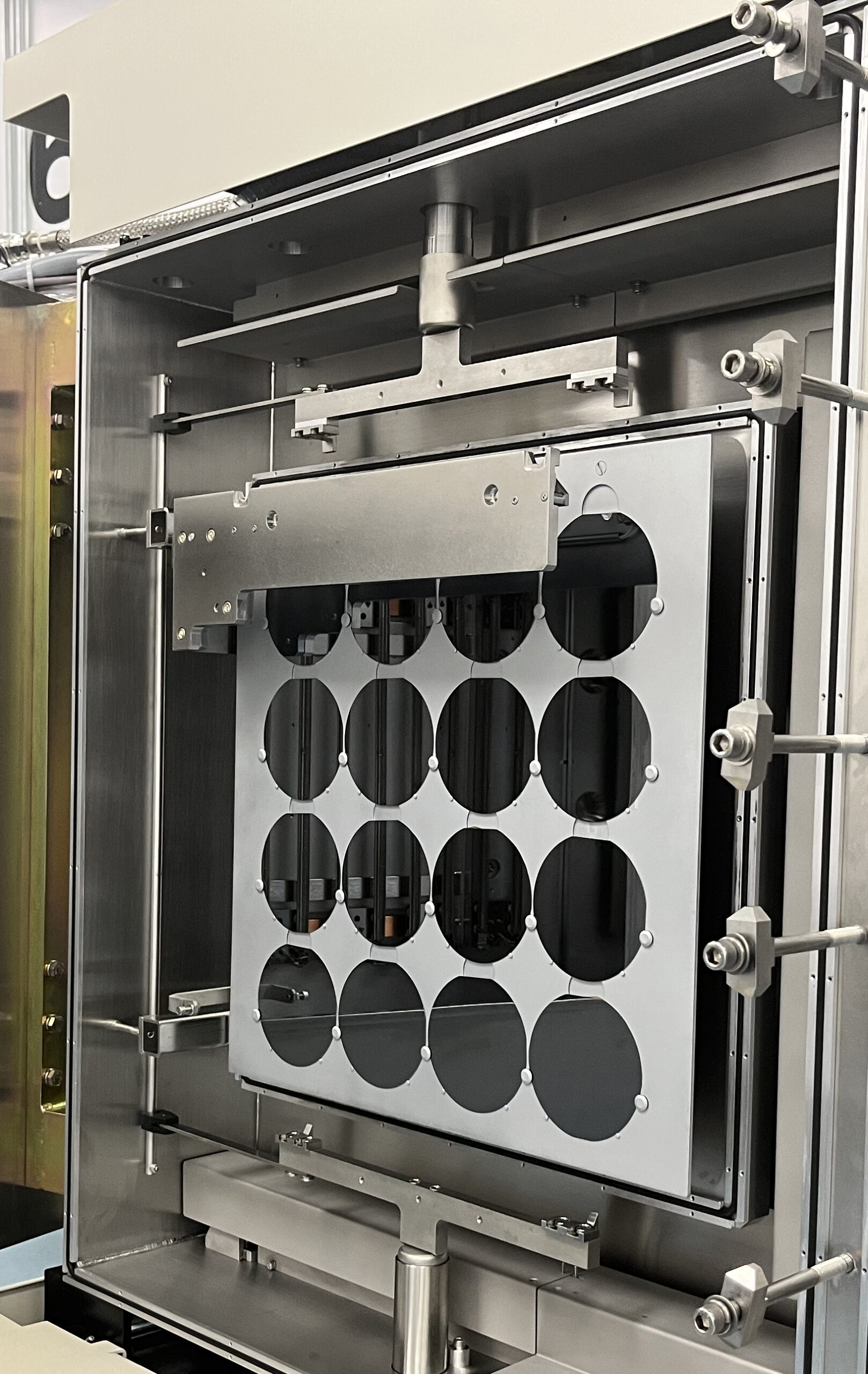

- Sputter Sources

- KDF has specially designed and patented sputter sources that are a great match for a reactive sputtering process. The LMM sputter source, for example, has nearly full-face erosion of the sputter target greatly reducing the build-up of reacted species on the target surface. Also, the inset sputter sources only have target material where the sputter plasma creates an erosion groove for high target utilization and limited area to build up reactive species on the target surface. By reducing the varied amount of reaction on a target surface decreases the chances of potential differences building up causing dreaded arcing and process instability.

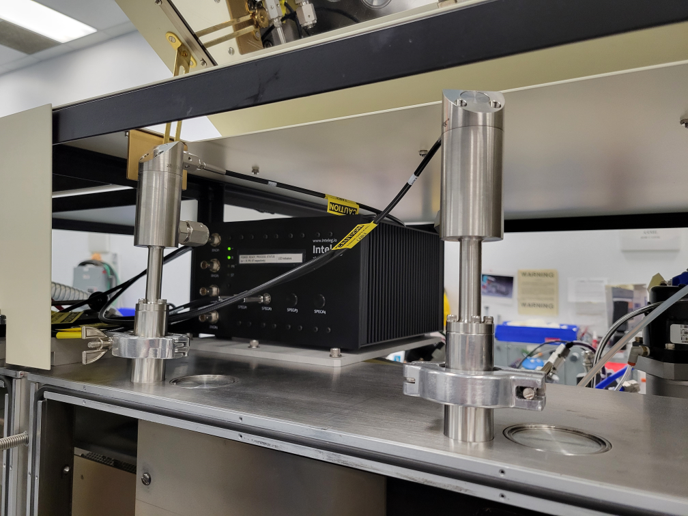

- In-situ Monitoring

- KDF effectively integrates Plasma Emission Monitoring (PEM) into the system with precisely placed optical sensors and easy-to-use software controls. The PEM tracks the relative emission intensity of the ionized species in the sputtering plasma and controls the reactive gas to maintain an emission intensity setpoint. This emission setpoint correlates to the deposition rate and reactive gas concentration in the films. It is a great solution for rapidly developing a reactive sputtering process and repeatably depositing films of similar quality.